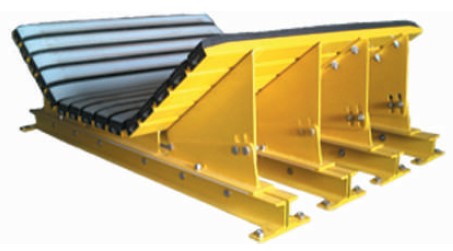

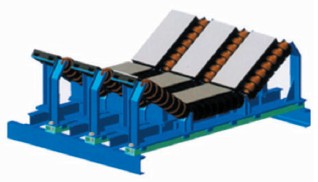

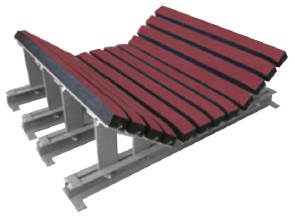

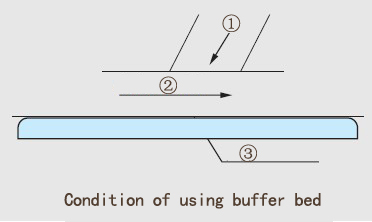

The placement corresponding to the lower of guide chute of belt conveyor uses heavy buffer bed to replace buffer idler. Buffer bar is made by the integrating vulcanization of the imported ultra-high polymers of polyethylene plate, natural rubber and aluminum alloy sections. It has buffer function to the materials to reduce the damage to belt by materials, and to the maximum extend prevent the tear of belt, which can correct the placement of materials, prevent the deviation of belt and prevent the spillover of materials.

|

1. Buffer Bar |

5. U-bar |

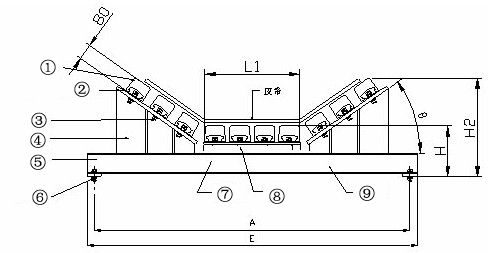

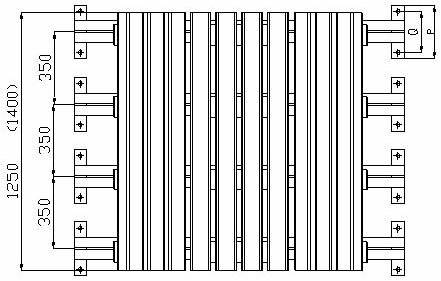

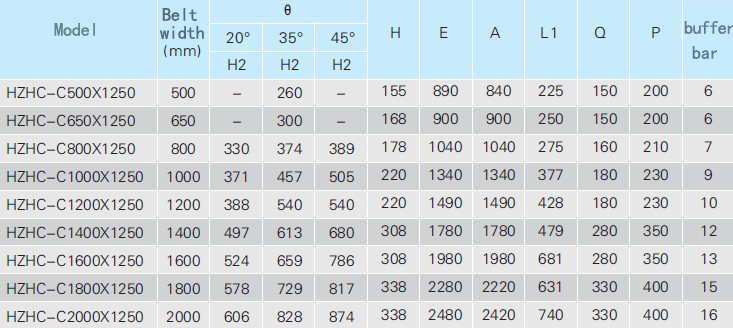

Impact bed model and parameter:

Note:

buffer bar:the Number of buffer bar

Correlation table between impact bed and impact idler:

|

Characteristics |

Buffer Bed |

Traditional Buffer Roller Group |

|

Anti-wear |

Longitudinal setting of buffer bed is consistent with the running direction of belt, which can effectively prevent the anti-wear of belt. |

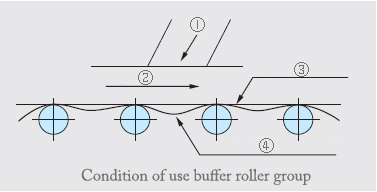

The space between buffer roller group is large, and the direction of roller shaft is perpendicular to the running direction of belt. The reinforcing steel bar in the materials and other foreign matters can be easily inserted to belt to get stuck between rollers so as to tear the belt; secondly, buffer roller alos can cause bounce under the impact of gravity to jump out of roller frame slot so that it cannot return the position and belt is stuck. |

|

Good anti-spill effect, and prevention from deviation of belt |

Buffer bar as a whole support the belt. The belt will not hollow when blanking, therefore blanking can be effectively corrected to prevent the deviation of belt or the spilling of materials. |

Buffer roller group will cause the falling of belt under heavy load, and the sealing effect is not good. |

|

Good overall buffer effect |

Buffer bed provides the full support of belt in blanking area with excellent overall buffer effect. |

The buffer roller groups are all in the single form, and the buffer effect is poor. |

In addition to the above advantages, the buffer beds also have the following characteristics:

◇ The surface material of buffer bar is HMW-PE. The surface is smooth and wear-resistant, which can reduce

the friction, and therefore reduce the impact of materials to the belt.

◇ Onsite installation and maintenance is simple and convenient, and the angle can be adjusted and the left and

right side beds can be laid flat so that the complete set is slid for installation from the side of conveyor. The

buffer bar can be supported singly or replaced in single side. Unscrewing T-bolt can change the buffer bar

quickly.

|

①: Blanking Position |

①: Blanking Position |