|

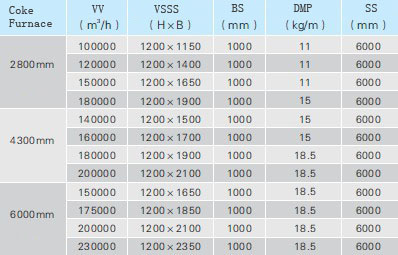

Beyond the coke car’s track, a ventilation slot is set along one side of the coke furnace. There are two tracks on the ventilation slot. In the upper, mobile dust removal trolley is equipped and beam is used to connect between trolley and coke car’s track. Gas fume collection cover and air exhaust bend are equipped, and air exhaust is connected with mobile dust removal trolley. The gas fume collected by collection cover via air exhaust bend enters ventilation slot through mobile dust removal trolley, and then is purified by the dust removal system of ground station. Mobile dust removal trolley prepares by itself the drive travelling mechanism for moving, and travels simultaneously with the coke car through electrical device. |

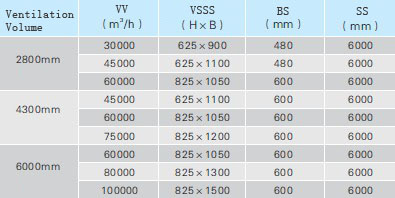

Note: VV= Ventilation Volume

|

|

One side or both sides of coke furnace top are equipped with ventilation slot on which the mobile dust removal trolley is set. Gas fume collection cover and air exhaust bend are equipped on coal loading cart, which connects with mobile dust removal trolley through air exhaust bend. Gas fume and dust after collected by collection cover via air exhaust bend enters ventiliation slot through mobile dust removal trolley, and then is purified by the dust removal system in ground station. The covering belt of ventiliation slot for dust removal of coal loading cart is high temperature resistant or heat-resistant belt. |

|

Compared with the commonly used gas fume reversing valve, the mobile ventiliation dust removal technology, in the application of dust removal of coke furnace, saves the time of para-position and turning on gas fume reversing valve and can improve the productivity of coke furnace.