HZGTD type steel belt bucket elevator (hereinafter referred to as HZGTD elevator) is a kind of widely used vertical elevating equipment. It is used to lift various kinds of dry bulk materials or small granular materials, such as cement, raw material, slag and micro powder, gravel, fertilizer, food, etc. HZGTD elevator is the product developed based on the advanced technology of the same kind of products in Germany brough by the company, with the characteristics of great delivery value, high hoisting height, low power consumption, smooth and reliable operation, long service life, etc., especially suitable for the lifting of entering kiln raw materials of new dry cement production line kiln tail and high-load cycle delivery of materials of closed circuit system of large-scale grinding machine, which can completely replace the imported equipment of the same specification.

HZGTD elevator traction components use high strength steel rubble belt, which overcomes the dynamic load caused by driving when chain and chain wheel are put into gear and is lighter than the lifting by chain. The operation is steady, and the material line load and line load of traction components can be lighter to reduce the size and self-weight of complete machine. At the same time, adhensive tape due to good elasticity and flexibility has damping effect when the bucket loads. Due to the use of high strength steel belt, the hoisting height of elevator and delivery value can be greatly improved. This product has been extremely widely used in various industrial countries, and has been widely used for the delivery systems in cement, chemical industry, coal, electricity, ports, food and other industries.

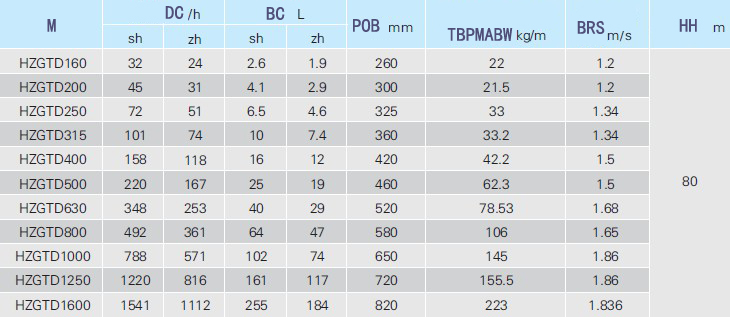

HZGTD sereis of elevators currently have eleven kinds of specifications and models: HZGTD160, HZGTD200, HZGTD250, HZGTD315, HZGTD400, HZGTD500, HZGTD630, HZGTD800, HZGTD1000, HZGTD1250, HZGTD1600.

| Performance characteristics of HZGTD elevators:

1. The hoisting height is high with the maximum up to 2. The delivery capacity is great with maximum up to 3. The temperature of materials can be up to 4. Traction pieces use anti-tear type steel cable belt, having the characteristics of high tensile strength, good 5. The arrangement between hopper is compact, with continuous extraction and continuous discharge. 6. Long service life, good operation reliablity, and trouble-free time can be oer 30, 000 hours. 7. Low power consumption. Compared with general elevators, over 30% of engergy can be saved and the use-cost is low. 8. Operation and maintenance are easy and convenient, and there are fewer wearing parts. Maintenance costs are reduced by more than 80% compared with general bucket elevators. 9. High structural accuracy, high strength and attractive appearance. 10. Good sealing and little environmental pollution. |

|

Structural characteristics of HZGTD elevator:

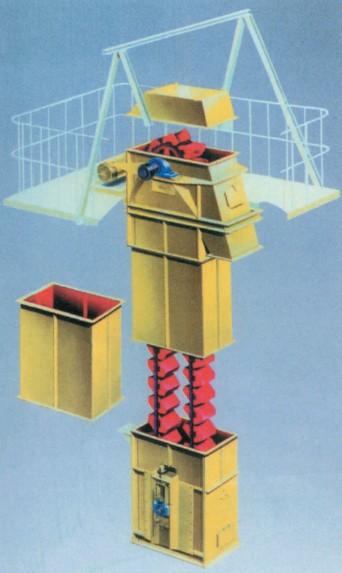

HZ GTD steel cable belt bucket elevator is composed of traveling parts, drive device, uppe device, middle case, lower device, protection device, etc.

1. Traveling parts: use special design, high strength steel cable belt with anti-tear is equipped with the speical

adhesive tape joints and fixed pieces of hopper to so that belt can reliably operate in the long term. The design

layout of hopper is reasonable, and there are different types of arrangement to ensure the continuous lifting and

discharging of materials.

2. Drive device: use the reducer of rectangular axis hardened tooth gear to directly connect with principal axis

of elevator, equipped with fluid coupling, slow overhaul motor and backstop. The structure of drive device is

impact and reasonable to achieve soft start.

performance, long service life and large friction force;

3. Upper device: the design of roller uses automatic centering device, and roller uses rubber coating of high

4. Middle case: use case of optimized design and dual-channel design to aviod the interference of vortex

brought by the belt of relatively high-speed operation and attached with strengthened angle iron.

5. Upper devcie: use gear rack tensioning device to adjust tensioning synchronously. Tail roller uses automatic

centering design and is additionally equipped with anti-deviation device and material level control instrument.

6. Protection device: this machine is equipped with anti-deviation device in the head and tail, which can

level control switch and rotary detector switch are equipped in the tail of elevator.

transmit the signal to central control room when the belt deviates to cut off the main power in time; material

Performance Parameters Table:

Note:

M: Model

DC: Delivery Capacity

BC: Bucket Capacity

POB: Pitch of Bucket

TBPMABW: Traction belt per meter and bucket weight

BRS: Bucket Running Speed

HH: Hoisting Height

Remark: Delivery capacity in the table is calculated by the 75% of filing.

Our company also produce other various kinds of bucket elevator equipment:

1. TD-type bucket elevator. 2. HL-type buket elevator. 3. PL-type bucket elevator. 4. NE plate chain elevator. 5. TH type bukcet elevator

TH Bukcet Elevator NE Plate Chain Bucket Elevator